·

A Quality Engineer’s

roles and responsibilities

If you are a

perfectionist and if you possess a bit of OCD behaviour (wants everything to be

corrected) if you possess a sight like an eagle, where you are efficient in

pointing out the finest spots of errors or malfunctions which are not seen by

all, and if you are courageous enough in taking preventive actions and are in-tolerant

against any mal-practice which could lead to failure of a product or could

affect company’s image than no field could give you satisfaction like this

which this field can.

·

Codes, Standards &

Specification

Code: -

Code is a standard that has been adopted by one or more government bodies and

can be enforced by law or when standard incorporated into a business contract.

Note-

Requirements are mandatory only if the code is in law in your country, if not

code will serve as generally accepted guidelines for design, fabrication,

construction and installation etc.

i.e.-

ASME Code, BS, DIN, IS etc.

Standard:-

Standard is a common language for defining quality and establishing product

safety criteria.

Or

Standards are documents

that establish engineering requirements, technical requirements for products,

practices, methods or operations, which builds confidence about the quality and

the lower cost of production.

i.e.- ASTM,ISO,API,MSS,IS etc.

Specification:- Specification or additional requirements for materials, components or services beyond the code or standard requirements often generated by private companies.

Why specification is required?

As specification allows the purchaser to include special requirements as per design and service conditions.

· What is the difference between Quality Assurance (QA) and Quality Control (QC)?

As per ISO 9000:2015,

Quality Control:- It is a part of quality management

focused on fulfilling quality requirements.

QC is a set

of activities for ensuring quality in products the activities focus on

identifying defects in the actual products produced.

QC is a corrective

tool.

Quality Assurance:- It is part of quality management

on providing confidence that quality requirements will be fulfilled

QA is a set

of activities ensuring quality in the process by which a product is developed.

QA is a managerial tool.

· Various measurement equipment (tapes, Vernier calipers, micrometer screw gauge, dial gauge, plug gauge, etc.)

Before knowing the measurement equipment used in engineering, it is very important to have a knowledge of various measuring units with their conversion, few examples are given below:-

1 mm = 0.0394 inch

1 inch = 25.4 mm

1 inch = 0.0254 m

1 foot = 304.8 mm

1 foot = 30.48 cm

1 foot = 12 inch

1 meter = 3 feet 3.37

inch (3.28084) foot

1 mm = 1000 micron

0.1mm = 100 micron

In any measurement

equipment, there is a most important term which is least count, least count is

the minimum measurement which equipment could take, as in engineering we often

have to deal with the tiny parts with accurate measurement as

The least count of the Vernier caliper is 0.02

mm, of micrometer & Bore gauge is 0.01 mm

To know more about Vernier caliper, micrometer and bore gauge and such other useful measuring equipment please do comment below

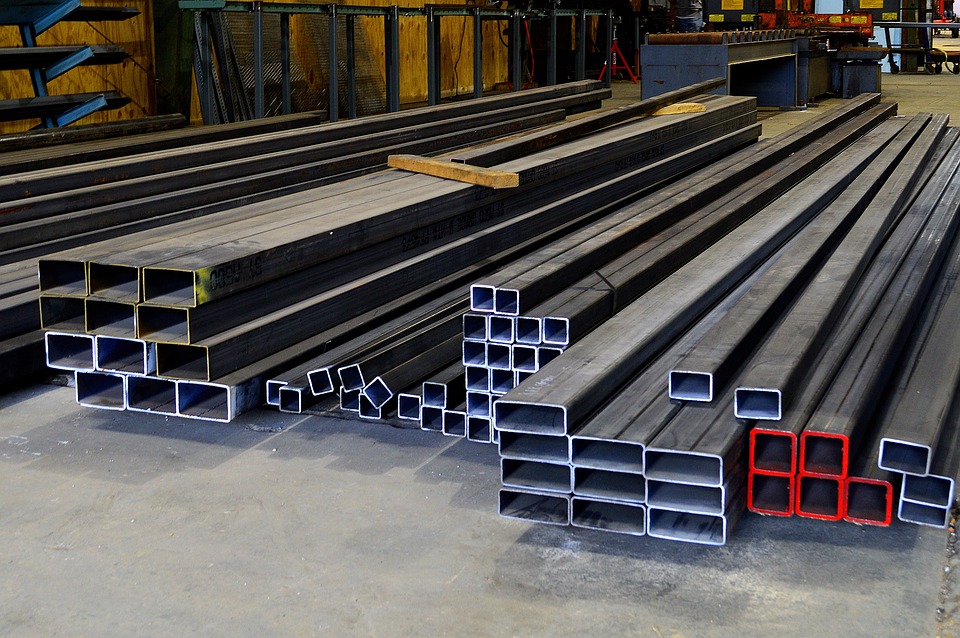

· Engineering materials used for manufacturing

Before you start production of any parts or components being a mechanical engineer the first thing that comes to your mind is material, whether it is about cost or it is about its usability, we can categorize them as

- Ferrous Metals like carbon steel, cast iron, etc.

- Non-Ferrous Metals like aluminium, copper

- Alloys

· Cast Iron

· Cast Steel

· Carbon Steel

· EN-8 steel consists of 0.8 % manganese, 0.4 % carbon, 0.25% silicon, 0.015% phosphorus, 0.015% sulphur.

· EN-9 steel consists of 0.60 % carbon, 0.80 % manganese, 0.35 % silicon, 0.06 % sulphur, 0.06 % phosphorous.

· EN-24 steel consists of 0.45 % carbon, 0.75 % manganese,

0.35 % silicon, 1.4 % chromium, 0.05 % sulphur

· EN-19 steel consists

Comments

Post a Comment